Navigating Tariffs:

Strategic Resilience from a Small Plastics Manufacturer

In recent weeks, Team 1 Plastics has been featured in multiple media outlets, including the Detroit News, Detroit Free Press, USA Today, and Switzerland’s RSI—for its response to the evolving tariff landscape. As a small plastics manufacturer embedded in the automotive supply chain, the company’s experience reflects the broader challenges facing thousands of U.S. suppliers as they navigate economic uncertainty.

While previous articles have highlighted Team 1 Plastics’ inclusion in the national conversation, this post offers a deeper look into the strategic decisions the company is making to adapt and remain resilient.

The Reality for Small Suppliers

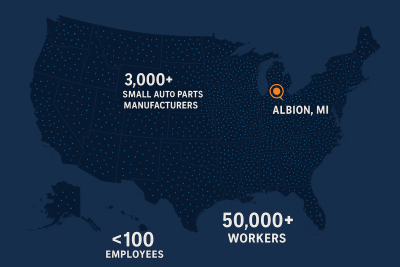

Team 1 Plastics operates out of Albion, Michigan, with 85 Team Members and a single facility. It produces plastic components—covers, switches, powertrain, and lighting parts—that ultimately find their way into vehicles made by GM, Ford, Toyota, Honda, Subaru, Stellantis and many others. With nearly 100% of its business tied to automotive, any disruption in the supply chain or cost structure has a direct impact.

Team 1 Plastics operates out of Albion, Michigan, with 85 Team Members and a single facility. It produces plastic components—covers, switches, powertrain, and lighting parts—that ultimately find their way into vehicles made by GM, Ford, Toyota, Honda, Subaru, Stellantis and many others. With nearly 100% of its business tied to automotive, any disruption in the supply chain or cost structure has a direct impact.

The recent 25% tariffs on imported auto parts, dies, steel, aluminum, and capital equipment have created significant financial pressure. For example:

- Dies sourced from Canada now cost 25% more, adding up to $175,000 annually in unexpected expenses.

- A new injection molding machine from Japan may carry a 25% tariff, increasing its cost by $75,000.

- The company’s facility expansion plan has been restructured to account for building material cost fluctuations, while continuing to move forward as part of its long-term growth strategy. It is just starting an 11,500 sq. ft. expansion to be completed by year-end.

These aren’t just line items; they represent strategic inflection points that affect hiring, pricing, and operational capacity.

Strategic Response, Not Just Reaction

Rather than respond with short-term fixes, Team 1 Plastics is taking a deliberate, business-minded long-term approach:

- Reevaluating sourcing strategies: While domestic suppliers are an option, limited capacity and rising prices require careful consideration of cost versus reliability.

- Maintaining transparent customer communication: The company has honored pricing on pre-tariff orders, absorbing the cost, while working collaboratively with customers on future projects.

- Continuing investment in growth: Despite the added expense, Team 1 Plastics is moving forward with key equipment purchases and staffing plans to support increased demand.

- Exploring new opportunities: Tariff shifts have prompted inquiries from Canadian and overseas customers, potentially opening doors to reshored business.

Industry Implications

According to U.S. Census data, over 3,000 auto parts manufacturers in the U.S. have fewer than 100 employees. These companies collectively employ more than 50,000 people and contribute billions to the economy. Yet they are the most exposed to volatility.

According to U.S. Census data, over 3,000 auto parts manufacturers in the U.S. have fewer than 100 employees. These companies collectively employ more than 50,000 people and contribute billions to the economy. Yet they are the most exposed to volatility.

As Vice President Gary Grigowski shared in the Detroit Free Press, “We’re little companies in little towns… and we’re making decisions that impact everything.”

This captures the essence of what it means to be a small supplier in today’s climate: every decision carries weight.

Looking Ahead

While the tariff situation remains fluid, Team 1 Plastics continues to navigate it with resilience and foresight. Strategic planning, open communication, and a willingness to adapt remain central to the company’s approach.

Tariffs may be an obstacle, but they have also become a catalyst, prompting Team 1 Plastics to sharpen its focus, strengthen its partnerships, and reaffirm its commitment to excellence in plastics manufacturing.

Leave A Comment