New Engineering Team Members Bring Value & Experience to Team 1 Plastics

Team 1 Plastics, a plastic injection molding company for the transportation industry, believes that building an exceptional company is the result of building exceptional teams with exceptional people. The company looks for Team Members who are honest, demonstrate a high level of integrity, have an eagerness to learn, contribute to a safe work environment, and value each person in a diverse workforce.

Team 1 Plastics, a plastic injection molding company for the transportation industry, believes that building an exceptional company is the result of building exceptional teams with exceptional people. The company looks for Team Members who are honest, demonstrate a high level of integrity, have an eagerness to learn, contribute to a safe work environment, and value each person in a diverse workforce.

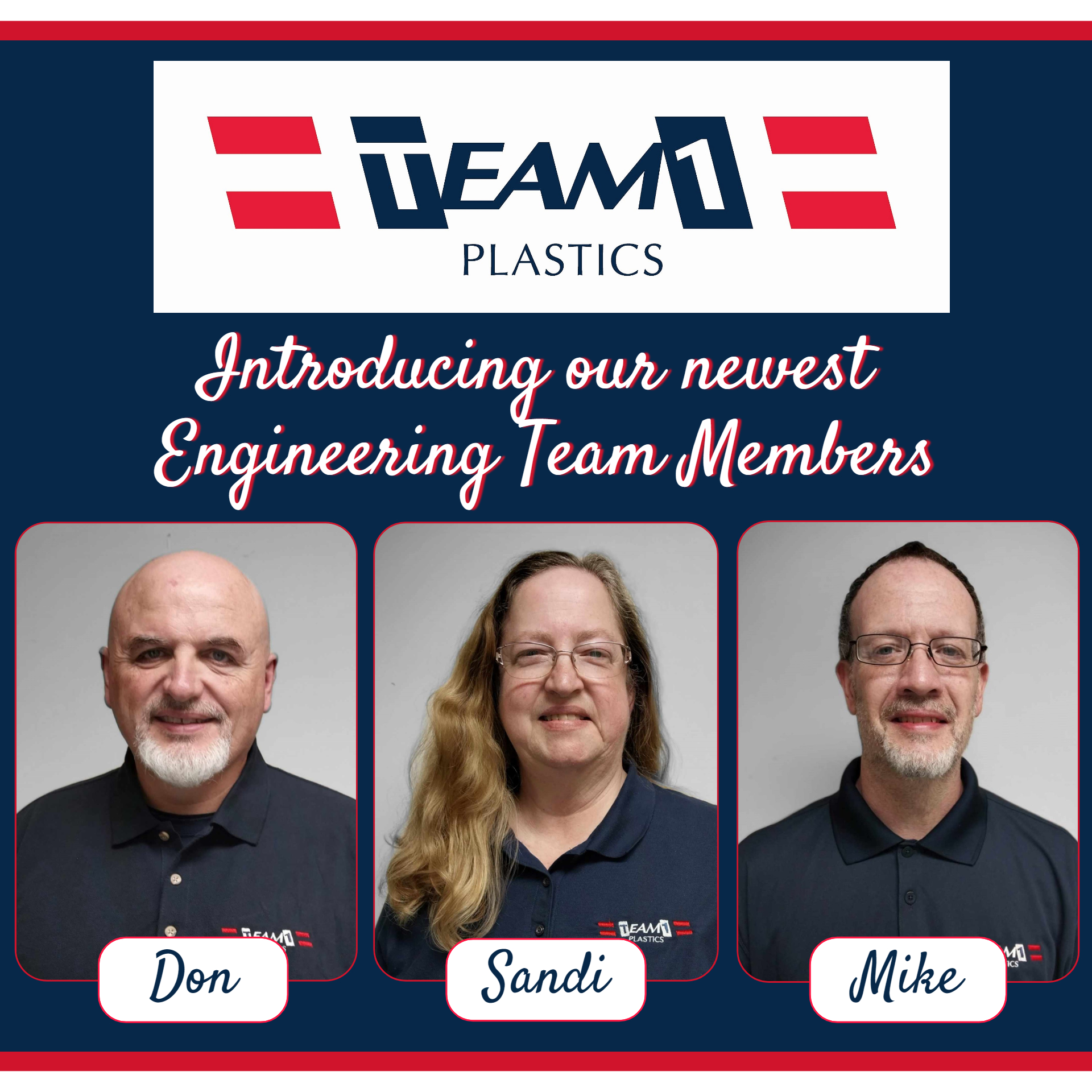

Today, Team 1 Plastics is proud to introduce three new Engineering Team Members: Don McCallum, Sandi Hodge, and Mike McBride.

Team 1’s Engineering Manager Dave Seedorf is excited to see what the future holds for the Engineering Team. Not only does Dave see the value in the combined experience of these three new Team Members, but he can already tell they are a good fit for the company. “All of them have great attitudes and are very easy to work with; fitting well into our Team 1 culture.”

DON MCCALLUM

DON MCCALLUM

Earlier this year, Don was contacted by a recruiter after a four-month-long job search. Within a week, the new Automation Specialist position at Team 1 Plastics was his. Being raised on a small farm north of Albion starting at age five, Don and his wife had moved back home from Iowa when he was offered the position. “I saw a lot of things during the interview in the factory that I had worked on before as components,” explained Don. “I knew how they worked, and it seemed to be a good fit.” Team 1 could not agree more that his addition to the team has been a “good fit.” As a third-generation engineer with an Associate of Arts and Science in Electronics Engineering Technology, and a Bachelor of Science in Engineering with a mechanical emphasis – Don brings much value to the company’s Engineering Team. In addition to his degrees, he has gained experience through a myriad of jobs – from two years as a Product Development Technician at John Deere to over 15 years as an Instrumentation Engineer while supporting Test Engineers and Technicians. Don proudly shared, “I have been finding solutions to problems since I was a child…I have worked over 30 jobs in various fields, and each of them has helped prepare me for this role.”

Filling a brand-new Automation Specialist position at Team 1, Don’s responsibilities have included end-of-arm tooling/cutters for new products, 3D printing, automation, and has served as a member of the Safety Team. Feeling “right at home” in this new position, Don described his time thus far at Team 1. “I started as a contract employee, but I was never treated as less than a member of the team. I get to use my head and my hands daily, creating and implementing solutions. I think that I have the best job in the plant. Some people dread getting up in the morning and having to go to work. I still dread getting up in the morning, but I get to go to work at the best job I have had.”

Team 1’s Engineering Manager Dave Seedorf explains the value of having Don on the Team in this new Automation Specialist position. “Our Automation Specialist is providing a direct responsibility and focus on automation activities within the plant. This is the first time we have had a Team Member with this focused automation responsibility…we believe this will allow us to integrate automation further within the facility – bringing new capabilities internally, such as 3D printing, Cobots, and automated assemble, along with expanding EoAT internal capability and focused oversight.”

SANDI HODGE

SANDI HODGE

At the beginning of this year, Sandi was laid off for the first time in her life. Finding herself on unemployment and browsing available jobs on Indeed.com, she came across a position working with Coordinate Measuring Machines (CMMs). Having 20 years of experience working with CMMs, Sandi knew that this could be a good fit. On May 8, she joined Team 1 Plastics as an Engineering Specialist – working 4 days a week in the company’s Metrology Lab. In addition to her extensive CMM experience, Sandi has years of experience in calibration. “I have been in plastics for 95% of my work life – close to 40 years ago,” she proudly shared. In the past 40 years, Sandi has worked as an Operator, Quality Technician, and Lab Coordinator – where she was in charge of calibration, customer relations, and layouts.

As a Team 1 Engineering Specialist, Sandi has been learning a lot over the past four months. “Although the number of tasks is not many, I stay very busy and the work is constant.” Those tasks have consisted mainly of layouts, calibration, and learning more about Computer-Aided Design (CAD). Enjoying the positive atmosphere, Sandi shared that she has worked at other places where there is “a lot of drama, so this is nice and refreshing. It feels like family already!” Team 1’s Engineering Manager Dave Seedorf knew that Sandi’s experience would make her a perfect fit, adding tremendous value to the company. “Sandi has brought a great amount of experience with her to Team 1. She has many years working with our metrology software PC-DMIS and CMM programming,” explained Dave. “Bringing her on board has allowed the Metrology Team to program and run two CMMs at a time on two different projects. Her capabilities have allowed us to have the staff internally to run projects independently – [this includes] programming, running CMM, performing manual checks, data entry, and completion. We have never been able to do this historically, but we are now achieving this. Not only it is working out much smoother for the Engineering Team, but also allows for better turnaround times, and more accurate data/communication internally.”

MIKE MCBRIDE

MIKE MCBRIDE

Mike’s story on what brought him to Team 1 Plastics is a bit different than most. “I had the privilege to service Team 1 while working with Sodick Plustech,” he explained. Impressed with the company’s hospitality and professionalism, Mike left “with only good things to say about Team 1.” Bringing value through experience with numerous injection molding companies, he has had quite an extensive career in plastics. Starting “under the wing” of a mold maker at Advanced Special Tools (AST) allowed Mike the opportunity to begin working on Sumitomo wire connector molds. From there, he started working on Sodick injection molding machines, then processing. “During my 15 years at AST, I was able to visit Japan, work with mold makers at Sumitomo Scottsville, and gain many relationships throughout the industry.” Additionally, Mike has worked for Graham Engineering at Tropicana in Florida, performing 4-layer blow molding to supply them with different sizes and types of blown bottles. After returning to Michigan, he has served as a Service Engineer with Sodick Plustech, Manufacturing Engineer for Summit Polymers’ plastics division, and worked with many types of overlay molds and interior products at Eimo Technologies.

Since the end of April, Mike has been a Process Engineer for Team 1 Plastics; a major win for the company’s Engineering Department. He shared that for the past five months, his responsibilities have included “perform[ing] trials on existing and new molds via the Teams Trial Calendar, and schedule board.” Working with end-of-arm tooling (EoAT) and cutting fixtures, programming robots, and communicating with suppliers for quotes are just a few of the many tasks Mike has had to tackle daily. “Mike’s years of experience have allowed him to hit the ground running,” shared Team 1’s Engineering Manager Dave Seedorf. “He is very familiar with our equipment, with tooling and processing capability, and has a GREAT attitude. He has been a great addition to our Engineering Team.” The feeling is certainly mutual. When asked what he enjoys most about Team 1, Mike responded, “The People! Great-blooded, can-do attitudes, nothing is impossible. I look forward to the long journey!!”

Leave A Comment