4 Keys to Improving New Product Launch

Most people would agree that the long-term success of any project is rooted in the management of the launch. If you do not put in the effort upfront in the planning, development, and launch of a new product, the product will, most likely, not be profitable. This is true whether your company is in retail, service, or manufacturing.

So, what are some keys to improving your new product launch? Dave Seedorf, Engineering Manager for Team 1 Plastics, a plastic injection molding company for the automotive industry, recently shared four keys to a successful new product launch.

Not surprising, the first key is communication. Seedorf said that he has learned over the years that it is imperative to build great relationships with the customer’s designers and program managers. “It makes communication much easier, and they usually respond much quicker to my questions.”

Communication begins with the Request for Quote (RFQ) process — the first step in Team 1’s new product launch. Seedorf said that in reviewing the customer’s RFQ data and requirements, “… it is critical to ensure that we are on the same page with the customer’s requests, eliminating assumptions.”

Of course, communicating with the customer is not enough. There needs to be communication among all the stakeholders. For example, Team 1 Plastics establishes an in-house New Product Launch Team to keep the information flowing to its Team Members. The Launch team, which meets regularly, is made up of representatives of several departments: Engineering, Production, Customer Service, Estimator, and Scheduling. Team 1 has found that utilizing a New Product Launch Team has helped them ensure that the timing of projects is met. It also provides a forum to discuss potential problems or road blocks and to develop solutions.

Cheaper is Not Better is the second key to improving the new product launch. Seedorf said that “searching for cheaper suppliers usually costs more in the long run.”

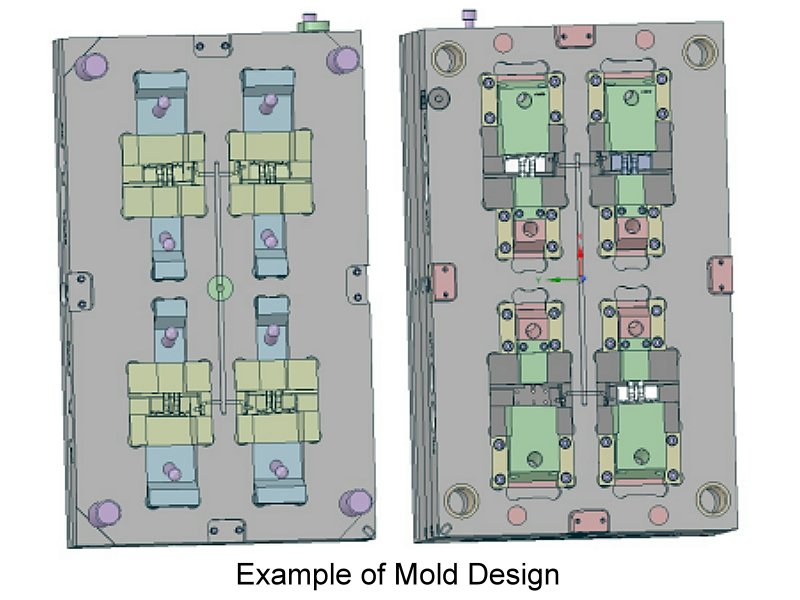

For a plastic injection molding company, the quality of a produced part is dependent on a quality mold. Seedorf shared that once when shopping for a mold supplier, Team 1 Plastics chose to use a supplier that had a cheaper upfront mold cost. However, when the launch process began the dimensional mold tuning stage, the charge by the supplier for standard dimensional adjustments to the mold exceeded expectations, causing the cost of the mold to be much greater than budgeted.

Don’t Over Source Your Supplier. You may be using the best quality and affordable supplier in your industry. But, if the work you give them exceeds their capacity, your new product launch could be in jeopardy.

Unfortunately, Team 1 Plastics learned this lesson the hard way. Seedorf shared the story of when the company had asked one of its suppliers to build new molds for three new products. “All of the molds were large, pretty busy, and complex.” That much work all at once for this supplier exceeded its capacity. Each of the molds was delivered late and was substandard, creating problems with part quality and delaying production.

Assess the Strengths and Weaknesses of Your Supplier is the fourth key. Each company has strengths and weaknesses. You want to utilize your supplier’s strengths to your advantage and to improve your new product launch. Conversely, you want to avoid your supplier’s weaknesses.

Seedorf said that Team 1 Plastics evaluates its suppliers to learn which type of mold each supplier excels in building and how well each company operates in standard conditions as well as under pressure. He said that one mold maker had built several molds for Team 1 without any noticeable problems. However, as the supplier’s company grew, it changed its operational processes. As a result of the changes, Team 1 began to experience quality issues from this supplier.

Remember these four keys when your company is contemplating its next New Product Launch, or, as Seedorf said, “Your product will most likely not be profitable due to cost overages, quality issues, missed shipments to customers, and, potentially for manufacturers, line down situations.”

Danielle Sheldon says:

Jeffery Carrel says:

Jeffery Carrel says: