How to Reduce Unscheduled Downtime

Unscheduled Downtime can cost you time and money, and potentially a loss of customers. No one wants that! So, how do you reduce Unscheduled Downtime?

Team 1 Plastics, a plastic injection molding company for the automotive industry, has developed three practices that have dramatically reduced the amount of its unscheduled down time.

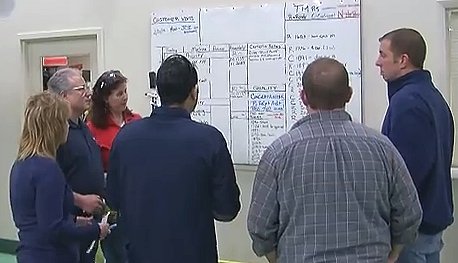

The first practice is its daily Huddle Meetings. Representatives from each of the departments meet together each morning to discuss any problems that have risen during the previous 24 hours. They also share updates on any current Hot Topics. The Huddle Meetings encourage the flow of communication and ensure that each item is being handled appropriately and allows prioritization of the most critical issues at hand.

The first practice is its daily Huddle Meetings. Representatives from each of the departments meet together each morning to discuss any problems that have risen during the previous 24 hours. They also share updates on any current Hot Topics. The Huddle Meetings encourage the flow of communication and ensure that each item is being handled appropriately and allows prioritization of the most critical issues at hand.

The second practice is Preventative Maintenance. Team 1 does a complete mold teardown after 25,000 shop count hours. And, each machine has a complete screw and barrel replacement after 5,000 run hours.

To help with coordinating the scheduling of the Preventative Maintenance, Team 1 posts a Maintenance Schedule Board in the plant. The five-member Maintenance Team works with the Logistics Team to create a two-week schedule. The schedule ensures that any customer-related issues, such as customer rejects or internal quality control concerns, are given the highest priority. It also allows the company to apply the right resources at the right time and to the right projects.

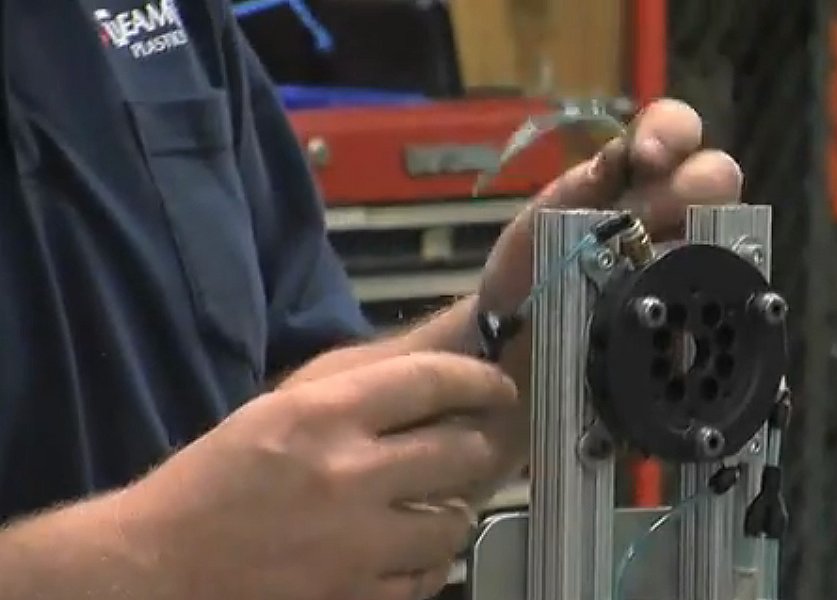

When a mold nears 25,000 shot count, the company’s Express Maintenance System sends a notification to let Logistics know that it’s time to schedule preventative maintenance. The Maintenance Team tears the die down; then, they inspect, clean, and lubricate all of its components. Any possible defects are photographed, and an analysis of previous samples is made. When all the concerns have been addressed, the die is reassembled and ready for production.

As part of the preventative maintenance practice, Team 1 keeps a spare screw and barrel system for each molding press machine. After 5,000 run hours on a machine, the current screw and barrel is replaced with the spare one. The Maintenance Team inspects the screw and barrel that was removed. If repairs or corrections are needed, it is shipped to an outside vendor for adjustments.

Team 1 admits that to keep a spare screw and barrel system for each machine, it was “… a huge cost up front, but unscheduled down time is down dramatically since we started doing it in the late 1990s.” This preventative maintenance practice has virtually eliminated any quality problems that were related to check rings.

Of course, not all maintenance is planned and scheduled. The third practice to eliminate downtime is Team 1’s preparedness for the occasional unexpected downtime due to a machine issue. This is accomplished by scheduling the Maintenance team to work on two different shifts, and by having all Maintenance Team Members on call 24/7.

By utilizing each of these practices, Team 1 Plastics has greatly reduced its unscheduled downtime, saving time and money, and most importantly, providing exceptional quality for its customers.

Danielle Sheldon says:

Jeffery Carrel says:

Jeffery Carrel says: