Making Automation Work

About ten years ago, Team 1 Plastics, a plastic injection molding company for the automotive industry, made a decision to focus on automation on its production floor. Craig Carrell, President and Co-owner, described the change. “One of the things that we’ve changed dramatically is the focus on automation. When we started, there were a lot of people at machines handling the parts; and over the last ten years, we’ve really seen that the way to go is to move out of direct labor. The automation and the information technology pieces have come down in cost, making it advantageous for a molder like us. So we’ve made a big push into automation.”

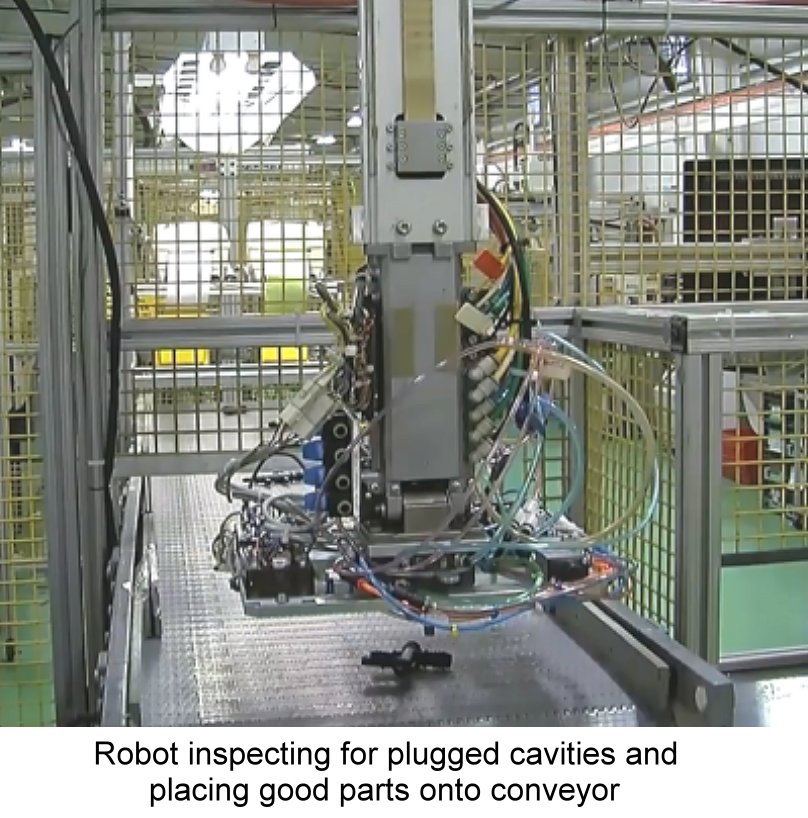

Every injection molding press at Team 1 is outfitted with some type of automation. Most have a rectilinear robot that is programmed to perform tasks such as extracting parts and placing them on to a nest and/or a conveyor. Some robots inspect the parts; some de-gate the parts and deliver them into final packaging.

Some presses utilize Gate Cutting robots either built into the End of Arm Tooling (EoAT) or as a stand-alone unit. Others have Selective Compliance Articulated Robot Arm (commonly referred to as SCARA robots). These versatile robots can perform many different operations. They can separate parts when more than one part is produced in a mold. They can count parts. They can perform cell packing. And, with different end of arm effectors, they can even do some measuring and testing.

At Team 1 Plastics, automation is used to minimize the manual handling of the parts, producing a more cost effective process. Automation is also used for efficiency of production. Tim Henry, Production Team Manager and Assembly Manager, put it this way, “A lot of what our automation does is designed to cut down on waste. We know that waste eats up profits.”

Even the way that Team 1 has organized its production floor is based on being efficient. Its plant has four production zones:

- Zone 1 consists of 11 injection molding machines ranging in size from 40 to 180 metric tons

- Zone 2 consists of 11 injection molding machines ranging in size from 25 to 180 metric tons

- Zone 3 consists of 3 injection molding machines ranging in size from 180 to 280 metric tons

- Zone 4 consists of 3 injection molding machines ranging in size from 180 to 300 metric tons

Due to the role that automation plays in Team 1 Plastics’ production environment, only one Production Operator is required in each zone. Parts in both Zones 1 and 2 tend to be small, and the machine and automation do the majority of the work, including placing the completed parts into a container. An alarm notifies the Production Operator to print a label, exchange the full container with an empty one, and move the finished goods into the Warehouse pick-up zone.

Due to the role that automation plays in Team 1 Plastics’ production environment, only one Production Operator is required in each zone. Parts in both Zones 1 and 2 tend to be small, and the machine and automation do the majority of the work, including placing the completed parts into a container. An alarm notifies the Production Operator to print a label, exchange the full container with an empty one, and move the finished goods into the Warehouse pick-up zone.

Parts produced in both Zones 3 and 4 tend to be larger and require more Operator contribution. The parts are placed via a rectilinear robot onto a conveyor. The conveyor then moves the parts to the Production Operator who may have a secondary operation to perform, such as a small inspection or layer packing. The conveyors in these zones are capable of running in either direction to accommodate the Production Operator’s work load for that day’s shift, eliminating extra movement by the Operator.

Printers, located at every press, enable the Production Operator to print a label after the parts are packed. The Operator attaches the label to the packing container and delivers it to the warehouse where the parts are scanned and added to the real-time inventory.

Team 1 Plastic’s production monitoring software, ProMon, also enhances efficiency. The software, available on the touch screen monitor located at each press, provides the Production Teams with a variety of useful feature and functions, including the most up-to-date manufacturing standards, a quick reference on what part defects to look for, order status, and run history, and the software gives the Production Team the ability to create Maintenance work requests.

The software also provides guides for the Set-Up Technicians. It provides detailed instructions of how to set-up the job for the specific part to be produced, what process parameters will be running, what alarms should be set, and what conditions they should look for. All of these functions are available to the Team without ever leaving the production zone.

Henry said that production packets, consisting of multiple documents, required for every production run, used to be kept in filing cabinets. Before the production changeover was produced, someone had to retrieve the multiple documents from the filing cabinets and build these production packets. After the job was completed, someone needed to break down the packets and return the documents to the filing cabinets. Sometimes the paperwork was misplaced or outdated, and the packet would need to be recreated before production could be run. This was a necessary, but tedious and time-consuming process. The addition of the ProMon software at every press completely eliminated this packet-building process.

Efficiency even determines where Team 1 stores each mold. The company used to store the molds at one end of the plant. Someone had to go get the tool when changing to a new part and take the previous tool back to the storage area. Now, the molds are stored near the presses which use them. Henry explains, “Storing the tool directly where you’re intending to use it is another example of eliminating waste.”

And, as mentioned previously, waste eats up profits.

Danielle Sheldon says:

Jeffery Carrel says:

Jeffery Carrel says: