Team 1 Plastics’ Focus on Continuous Improvement Reaps Results

Team 1 Plastics, a plastic injection molding company for the automotive industry, is continuously looking for ways to improve. Two specific areas of focus for improvement in 2017 are reduced rejects and improved on-time delivery. In both categories, the first quarter of 2017 was the best ever in the company’s 30-year history. Rejects were reduced by over 50%, and the company achieved 100% on-time delivery on most days and, for the quarter in total, near 100%. And, the company has continued to maintain this level of excellence during the second quarter of 2017.

Team 1 Plastics, a plastic injection molding company for the automotive industry, is continuously looking for ways to improve. Two specific areas of focus for improvement in 2017 are reduced rejects and improved on-time delivery. In both categories, the first quarter of 2017 was the best ever in the company’s 30-year history. Rejects were reduced by over 50%, and the company achieved 100% on-time delivery on most days and, for the quarter in total, near 100%. And, the company has continued to maintain this level of excellence during the second quarter of 2017.

Why the focus on these two specific areas? Better service to its customers and reduced costs.

In the past few years, Team 1 had realized a significant increase in labor costs for sorting of parts due to quality issues. And, during the same time, the company’s costs for expedited freight had risen significantly. Dave Sanford, Quality Manager for Team 1 Plastics, explained that capacity constraints, improper scheduling, and quality problems were some of the factors that had led to these increased costs. He also noted that Team 1 Plastics had received a large job order which included injection molds that had been built overseas. Unfortunately, the quality of these molds was “inadequate, causing additional sorting and expediting.”

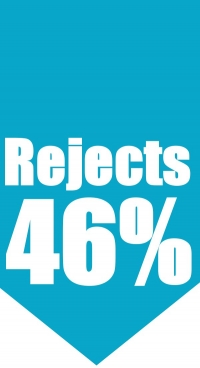

How is Team 1 doing? “Customer rejections through two quarters of 2017 have been reduced by 46% in comparison to last year. Expedited freight costs have been reduced by 65%, and the labor cost for sorting of parts has been reduced by 39%,” Sanford said.

Sanford then spoke about this significant improvement. “There is no single procedure, process, or person that helped turn this around. It was clearly a team effort. We reinstituted our corrective action meetings with a cross-functional team. We also added a Process Tech to both shifts and a Quality Engineer to the Days shift to assist with problems and make improvements. We can now dedicate a small team to a problem and have them follow it through until it is validated. And, this can happen during a trial run when we will get results back within a few hours. In years past, because we did not have this option, most of the quality troubleshooting was being done while running parts to fulfill an order.”

Sanford also said that “capacity per machine was rebalanced, providing adequate time for each job to run as needed and allowing Team 1 to put ‘safety stock’ [surplus parts] into inventory.” Having “safety stock” gives Team 1 the option of shutting down production if a mold or press needs work and completing the job order by shipping parts from the safety stock. “By doing this,” Sanford said, “We naturally reduce sorting and expediting expenses.”

Sanford concluded, “We still have more improvements to make; but over the last year, we have made a huge step in the right direction.”

Danielle Sheldon says:

Jeffery Carrel says:

Jeffery Carrel says: